|

| Contact Us |

| |

Add: Room 1204, Tiantong nan road 577-39#, Yinzhou District, Ningbo 315100, China

P.C: 315100

Tel: +86-574-88189478

+86-574-28870228

E-mail:nord@cnool.net

E-mail:admin@nord-foundry.com

|

|

|

|

|

Welcome to Copper parts-001 |

|

|

| Nord Machinery Co., ltd, starting since 2001, is a Chinese foundry, specialized in manufacturing all kinds of copper parts,carbon steel, alloy steel,ductile iron,grey iron,high Cr iron casting parts, which are used in the field of transportation equipment(train parts/vessel parts), agricultural machinery, mining machinery, rubber machinery, some other heavy machineries, etc. Such goods are exported mainly to the North America, Europe, Australia South Africa market. Our foundry is located in Ningbo city, which is one of the largest port cities in China and also the China Investment casting and Sand casting production base. If you have any other question, please feel free to contact us. |

|

|

|

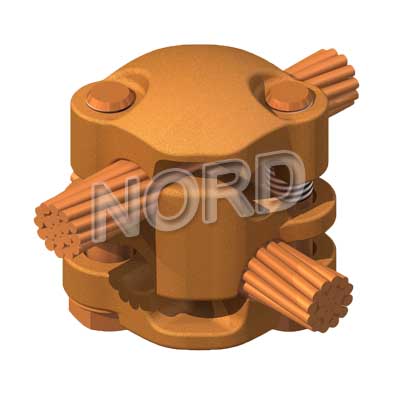

Copper parts0104

Detailed Feature:

|

1.Product name |

copper foundry parts; brass foundry parts |

|

2.Processes |

|

|

3.Material Range |

Copper, Brass, Bronze, pure copper, red bronze, rose copper, Nickel, silver color, copper strip, copper bar, copperizing, coppering, Copper Electroplating, copper plating. |

|

4.Certification system |

ISO 9001 Registed;Strict material inspection;Exact dimension control;100% quality control |

|

5.Prompt quote & Leadtime guarante |

30 -40 days |

|

6. Application Fields |

Construction, Industry, Agriculture, etc |

|

7.Payment Term: |

T/T, Sight L/C,etc. |

|

8. Trade Terms: |

FOB, CIF,etc |

|

9.Material Standard: |

ASTM, AISI, ASME, SAE,NF EN, DIN EN, ISO, BS EN, SS, etc. |

|

10.Software for Specification Drawings: |

Pro/E, Solid works, PDF, JPG, Auto CAD. |

|

11.Inspection Equipment: |

Spectrograph, Tensile Strength Test Machine, Impact Test Machine, Rockwell Hardness Tester, Brinell hardness Tester, Leeb Hardness Tester, Vickers Hardness Tester, HX-MIAS, Magnetic Defect Detector, Ultrasonic Flaw Detector, X-Ray Test. |

|

12.Machining Equipment |

CNC Machining Shop, Lathe, Milling Machine, Drilling Machine, Boring Lathe, Grinding Machine, Heat Treatment Furnaces. |

|

13.Dimension Inspection |

Calipers, Height Gauge, Micrometer Calipers, Inside Caliper Gauge, Angle and R Gauge, three coordinates measuring instrument. |

|

14.Surface Treatment: |

Cold/Hot Zn Plating, Blackening Treatment(Salt Spray Test 48-96 hours), Ni Plating, Cr Plating, Spraying Undercoat, Anti-Rust Paint, Surface Paint, Plastic Paint. Coated Anti-Rust Water, Anti-Rust Oil,etc. |

|

15.Surface Heat Treatment: |

Medium Frequence Quenching, High Frequence Quenching and Carburizing and Quenching, Oil Quenching, Water Quenching, Normalizing, Temper,Annealing,etc |

|

16.Heat Treatment Machine: |

Mesh-belt Firnace, Carburizing Quench Furnace, Chamber Furnace, etc. |

|

17. Annual Output: |

8000-10000 Ton |

|

17. Packing: |

Wood Carton, Cardboard carton, or according to customers' requirements. |

|

18.Supplier Information: |

China Zhejiang Ningbo copper foundry factory; China Ningbo foundry company; China Ningbo brass foundry co.,ltd; China Ningbo copper foundry inc; China

Ningbo copper foundry corporation; China Ningbo brass foundry manufacturer; China Ningbo copper foundry Supplier; China Ningbo copper foundry part; China Ningbo steel foundry; |

|

19..Place of Origin: |

Ningbo,China |

|

|

|

|