|

| Contact Us |

| |

Add: Room 1204, Tiantong nan road 577-39#, Yinzhou District, Ningbo 315100, China

P.C: 315100

Tel: +86-574-88189478

+86-574-28870228

E-mail:nord@cnool.net

E-mail:admin@nord-foundry.com

|

|

|

|

|

Welcome

to Forging Flange |

|

|

| Nord Machinery Co.,LTD is a leading forging factory in Ningbo city, Zhejiang Province, China. To control the standard production, weve been registered with ISO9001 and acquired certification of various classification societies, such as CCS, ABS, DNV, BV, GL, LR, etc. Our workshopnbsp is equiped with 1 set of 1ton free forging hammer, 1 set of 3ton free forging hammer, 1set of 5ton free forging hammer, 1set of 3000tonnbsp and 1 set of 7800ton oil press hammers. Besides these, we have also kinds of machining equipments, such as 5 sets of 5 diameters vertical lathe, 7 sets of 3m-18m long horizontal lathe, 1set of planer type miling machine, CNC, 15m long deep hole drilling machine. Weights of our forgings ranges from 20kgs to 80000kgs. Diameters ranges from 50mm to 5000mm, with max.length of 18m.br / The Inspection equipments we own includes Ultrasonic test equpment, Magnetic test equipment, material laboratory amp Impact testing equipment.br / Ningbo Nord Machinery Co., Ltd manufactures different sizes of forging parts, such as liner tubes, shafts, blockes etc. We have two kinds of forging technics, Open dienbsp forging (Hot forging,Drop forging or Heavy forging) amp Closed die forging. The forging parts are used for mining equipment, shipbuilding, Engineering machine, oil amp power transportation equipment ect. Mainly materials we using are alloy steel, Carbon steel,stainless steel... Now our annual export capacity is more than 20000tons. We export forging parts to America, Canada, Spain, Australia, U.K, Germany, Sweden, Danmark, Norway etc, and supply good after service. br / We warmly welcome your drawings for production any time! Hope to work with you based on mutural Benefit! |

|

|

|

|

| Process Description |

Open Die Forging Technological Process

|

|

|

1, Melting Customized Raw Material

Melting customized raw material according to chemical composition which customer provide. |

2, Spectrum Testing

We will continue produce after chemical composition approval. |

|

|

|

3, Cutting Steel

Cutting steel into the best proportion for forging. |

4, Annealing

Annealing for raw material to ensure there is no cracks in products during forging process. |

|

|

| 5, Forging Process |

6, Rough machining |

|

|

|

7, Heat Treatment

We could do different heat treatment ways according to mechanical properties which customer request. |

8, Inspect Mechanical Properties

We will cut a test specimen from product body to test, and continue producing after test specimen approval. |

|

|

|

9, Machining

Machining according to drawing dimentions or customer's delivery dimention request. |

10, Magnetic Particle Testing (MT)

We usually use MT to inspect surface cracks of products. |

|

|

|

11, Ultrasonic Testing (UT)

We usually use UT to inspect the size of products internal defect, and tell approval or not according to customer's UT grade request. |

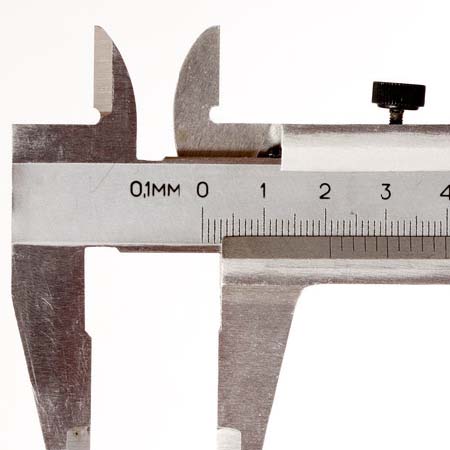

12, Final Inspection

We will do visual inspection and inspect dimentions of products by measuring inplements after finishing. |

|

|

| 13, Packing |

14, Transport |

|

|

|

|

|