| Process Description |

| Valves |

|

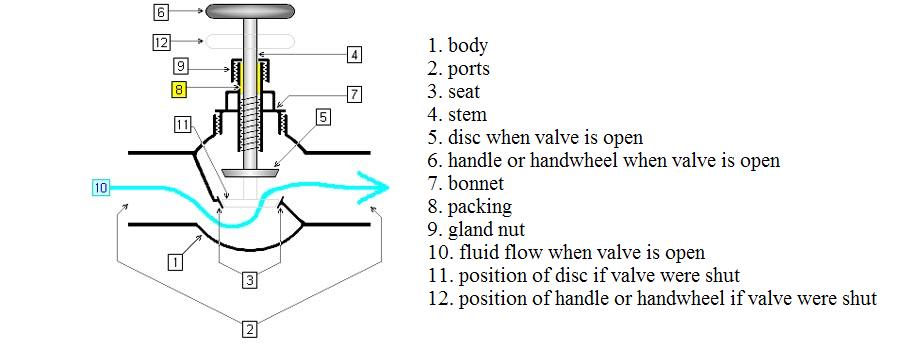

| A valve is a device that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries) by opening, closing, or partially obstructing various passageways. Valves are technically valves fittings, but are usually discussed as a separate category. Valves are found in virtually every industrial process, including water & sewage processing, mining, power generation, processing of oil, gas & petroleum, food manufacturing, chemical & plastic manufacturing and many other fields. Valves may be operated manually, either by a handle, lever, pedal or wheel. Valves may also be automatic, driven by changes in pressure, temperature, or flow. |

|

| Valves are widely used in the field of water treating equipments industry, chemical equipments industry, petrifaction industry, petroleum equipment industry, papermaking industry, mining equipment industry, electricity equipment industry, liquefied gas equipment industry, food equipment industry, pharmacy equipment industry, water supply and drainage system, mechanical equipment valve, electronic industry valve, civil construction valves, industry pipeline valves, GE parts, industry equipments, fire fighting system, filter equipments, environmental protection equipments. Besides these, they can also be used for nuclear power industry, thermal power equipments, building industry and the special industries. |

| Usually used material for valves: gray iron, ductile iron, WCB, LCC, carbon steel, casting steel, SS304, SS316, CF8, CF8M、CF3、CF3M, duplex stainless steel and special steel. Pressure grade: 0.6~32.0Mpa, inside nominal diameter: DN15~DN2000, applicable temperture:-150℃~+700℃. |

| Our company is export-oriented, and the Valves have already been sold to Australia, United States, Canada, UK, (Britain, England), Holland, France, Germany, Denmark, Sweden, Finland, Russia, Spain, Portugal. Italy, etc. |

|

Valves Technological Process

|

| We will produce valves according to the International Production Standard. All valves and it's components will be tested, including pressure testing, tightness testing and whole body debugging testing. All valves will have to pass the above testings before delivery. We warmly welcome customer representatives to come to inspect the valves any time! |

| Links:China Valve Foundry, China Valve casting, China Valve factory,China Valve manufacturer,China Valve company,China Valve supply,China Valve Co.,LTD,China Valve Inc,Ningbo Valve Foundry, Ningbo Valve casting, Ningbo Valve factory,Ningbo Valve manufacturer,Ningbo Valve company,Ningbo Valve supply,Ningbo Valve Co.,LTD,Ningbo Valve Inc,Zhejiang Valve Foundry,Zhejiang Valve casting, Zhejiang Valve factory,Zhejiang Valve manufacturer,Zhejiang Valve company,Zhejiang Valve supply,ShangHai Valve Foundry, ShangHai Valve casting, ShangHai Valve factory,ShangHai Valve manufacturer,ShangHai Valve company,ShangHai Valve supply,Shanghai Valve Co.,LTD,Shanghai Valve Inc, |

|

|

|